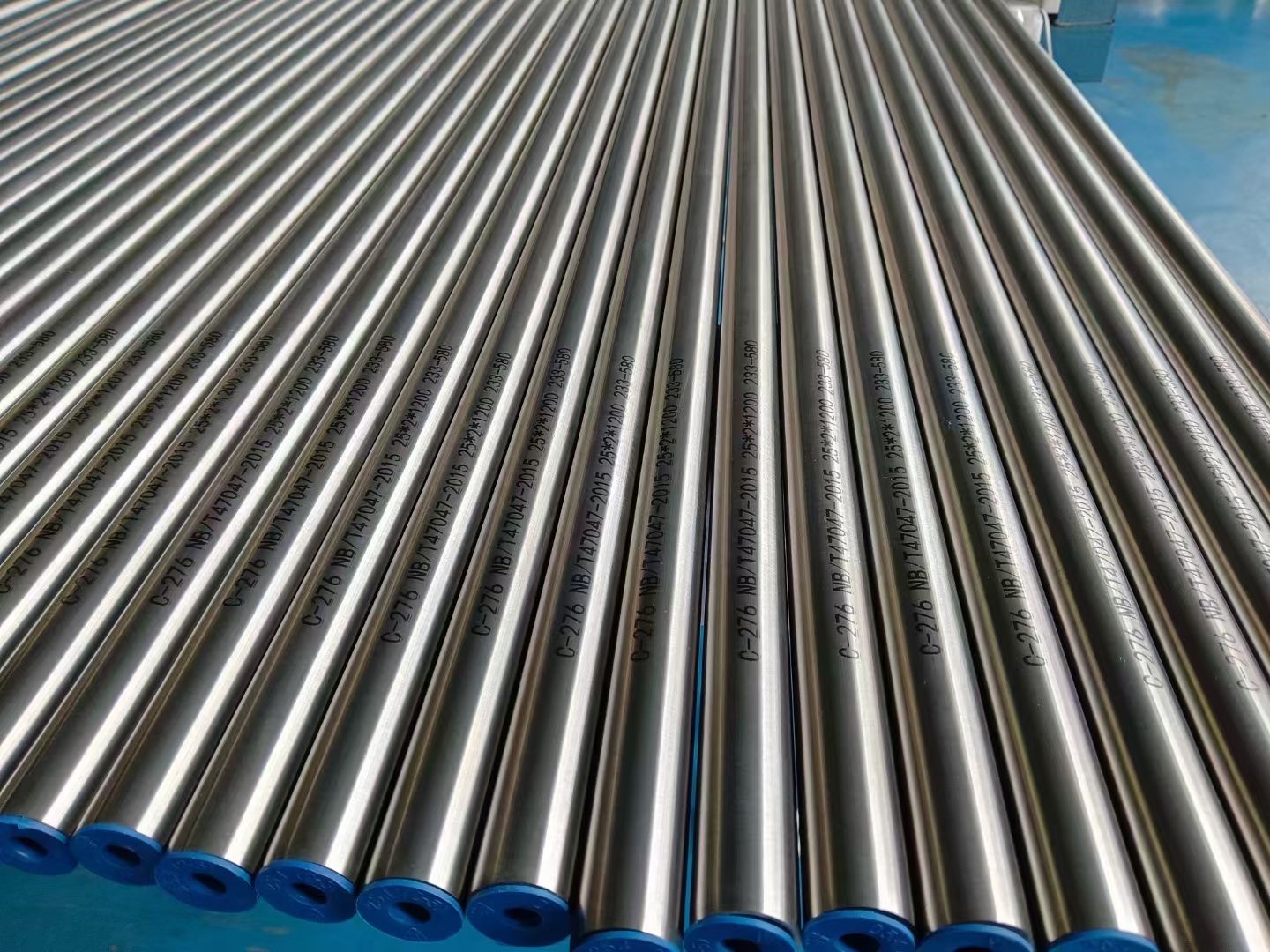

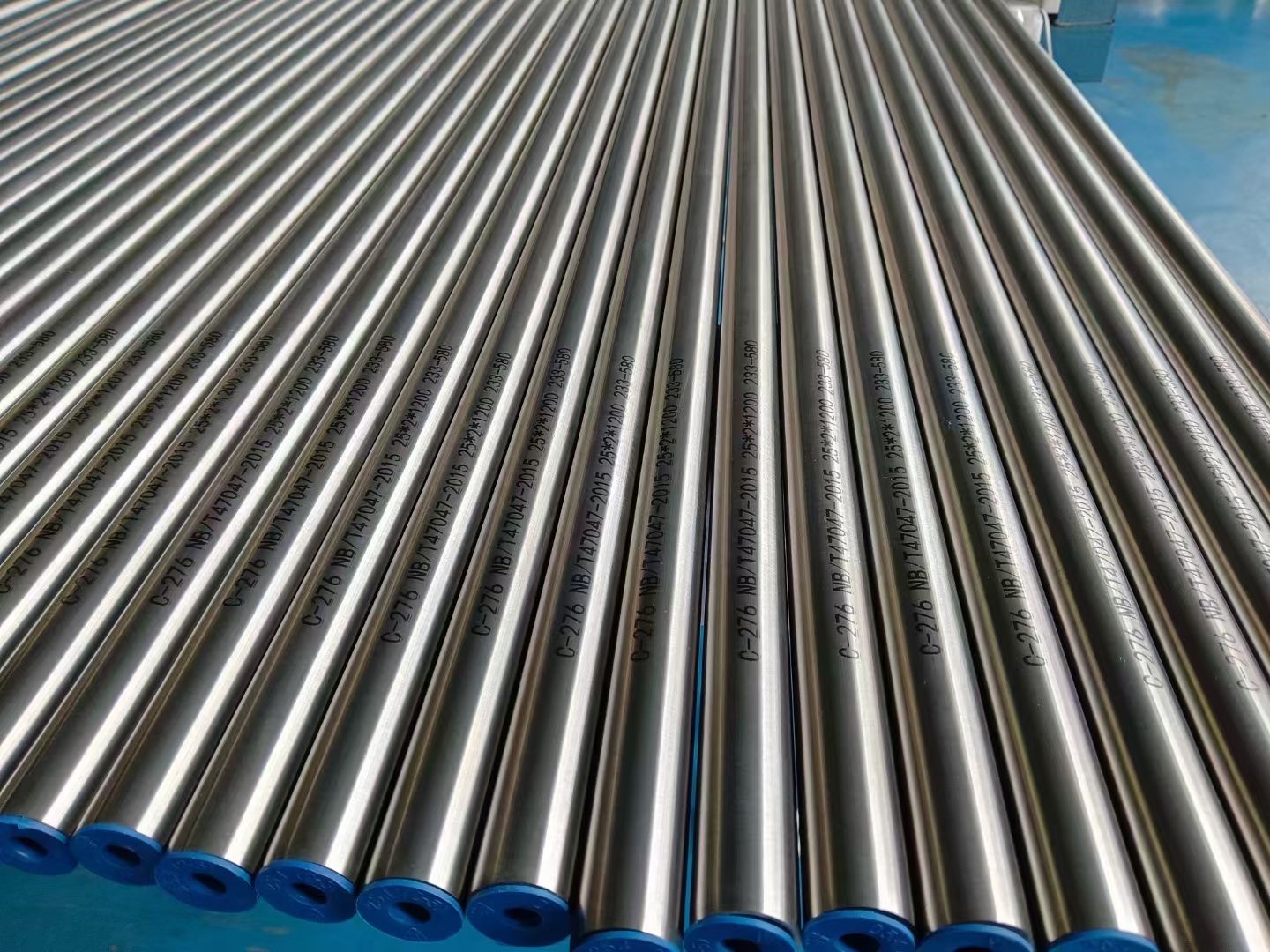

Seamless steel pipes are a critical component in various industrial applications due to their strength, durability, and versatility. Unlike other types of pipes, seamless steel pipes do not have any welded joints or seams, making them more robust and reliable for carrying fluids and gases under high pressure. In this article, we will explore the intricacies of seamless steel pipes, including their manufacturing process, advantages, and common applications.

What is a Seamless Steel Pipe?

A seamless steel pipe is a type of pipe made from a single piece of metal without any welding seams or joints. This seamless construction gives these pipes superior strength and resistance to corrosion and pressure. Seamless steel pipes are typically made from high-quality carbon steel, alloy steel, or stainless steel. They are widely used in industries where high precision, reliability, and strength are required.

The absence of seams ensures that the pipes can withstand significant pressure and temperature variations without the risk of leaks or bursts. This makes them ideal for use in critical applications such as oil and gas transportation, chemical processing, and power generation.

Manufacturing Process of Seamless Steel Pipes

The production of seamless steel pipes involves several stages, each crucial to ensuring the final product's quality and performance.

1. Raw Material Selection

The process begins with the selection of high-quality raw materials. Typically, billets or solid round steel bars are used. The choice of material depends on the intended application and the required properties of the finished pipe.

2. Heating

The selected raw material is heated to a high temperature to make it malleable. This is usually done in a rotary hearth furnace, which ensures uniform heating.

3. Piercing

Once heated, the billet is pierced using a piercing mill to create a hollow tube. This process involves rolling the billet between two rollers while a mandrel pierces through the center, forming a hollow shell.

4. Elongation

The hollow shell is then elongated to the desired length using a series of rolling mills. This step also helps to refine the pipe's dimensions and improve its mechanical properties.

5. Sizing and Stretch Reducing

After elongation, the pipe undergoes sizing and stretch reducing processes to achieve the final dimensions and ensure uniform wall thickness. This is done using a sizing mill and a stretch reducing mill.

6. Heat Treatment

To enhance the pipe's mechanical properties and relieve internal stresses, it undergoes heat treatment processes such as annealing or quenching and tempering.

7. Inspection and Testing

Finally, the seamless steel pipe is subjected to rigorous inspection and testing to ensure it meets the required standards and specifications. This includes non-destructive testing methods like ultrasonic testing and hydrostatic testing to check for defects and ensure structural integrity.

Advantages of Seamless Steel Pipes

Seamless steel pipes offer several advantages over their welded counterparts, making them the preferred choice for many industrial applications.

1. Superior Strength

The seamless construction of these pipes eliminates the risk of weak points at weld seams, providing superior strength and durability. This makes them ideal for high-pressure applications.

2. Corrosion Resistance

Seamless steel pipes are highly resistant to corrosion, especially when made from stainless steel or alloy steel. This ensures a longer lifespan even in harsh environments.

3. Uniformity

The absence of weld seams ensures uniformity in diameter and thickness throughout the length of the pipe. This is crucial for applications requiring precise dimensions.

4. Versatility

Seamless steel pipes can be manufactured in various sizes and thicknesses to suit different applications. They are also suitable for both hot and cold working processes.

5. Reliability

Due to their robust construction and uniformity, seamless steel pipes are more reliable under extreme conditions such as high pressure, high temperature, and corrosive environments.

Common Applications of Seamless Steel Pipes

Seamless steel pipes find applications in a wide range of industries due to their exceptional properties. Here are some common uses:

1. Oil and Gas Industry

Seamless steel pipes are extensively used in the oil and gas industry for drilling, production, and transportation purposes. Their ability to withstand high pressure and corrosive environments makes them ideal for transporting oil, gas, and other hydrocarbons.

2. Chemical Processing

In chemical processing plants, seamless steel pipes are used for transporting aggressive chemicals and fluids. Their resistance to corrosion ensures long-term reliability in such harsh environments.

3. Power Generation

Power plants use seamless steel pipes in various systems such as boilers, heat exchangers, and condensers. Their ability to handle high temperatures and pressures makes them suitable for these critical applications.

4. Automotive Industry

Seamless steel pipes are used in the automotive industry for manufacturing various components such as exhaust systems, hydraulic systems, and fuel injection systems. Their strength and durability ensure reliable performance under demanding conditions.

5. Construction Industry

In construction, seamless steel pipes are used for structural applications such as scaffolding, columns, and beams. Their superior strength-to-weight ratio makes them an excellent choice for load-bearing structures.

6. Aerospace Industry

The aerospace industry relies on seamless steel pipes for manufacturing aircraft components such as hydraulic lines, fuel lines, and structural elements. The high strength and precision of these pipes ensure safety and reliability in flight operations.

In conclusion, seamless steel pipes are a versatile and reliable choice for various industrial applications due to their superior strength, corrosion resistance, uniformity, and versatility. Their seamless construction ensures durability and performance under extreme conditions, making them an essential component in many critical systems across different industries.